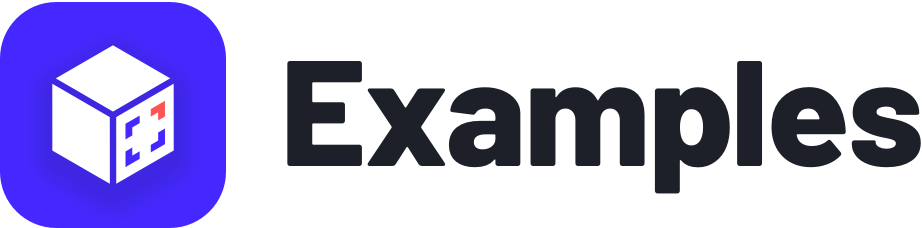

Fette Compacting 3D Machine Presentation with SmartVu®

Fette Compacting leverages SmartVu® 3D technology to transform tablet press documentation. Interactive animated models replace static manuals, enabling 360° exploration, real-time mechanical sequences, and transparent views of internal operations—reducing training time by 40%.

Revolutionizing Technical Documentation Through Interactive 3D Visualization

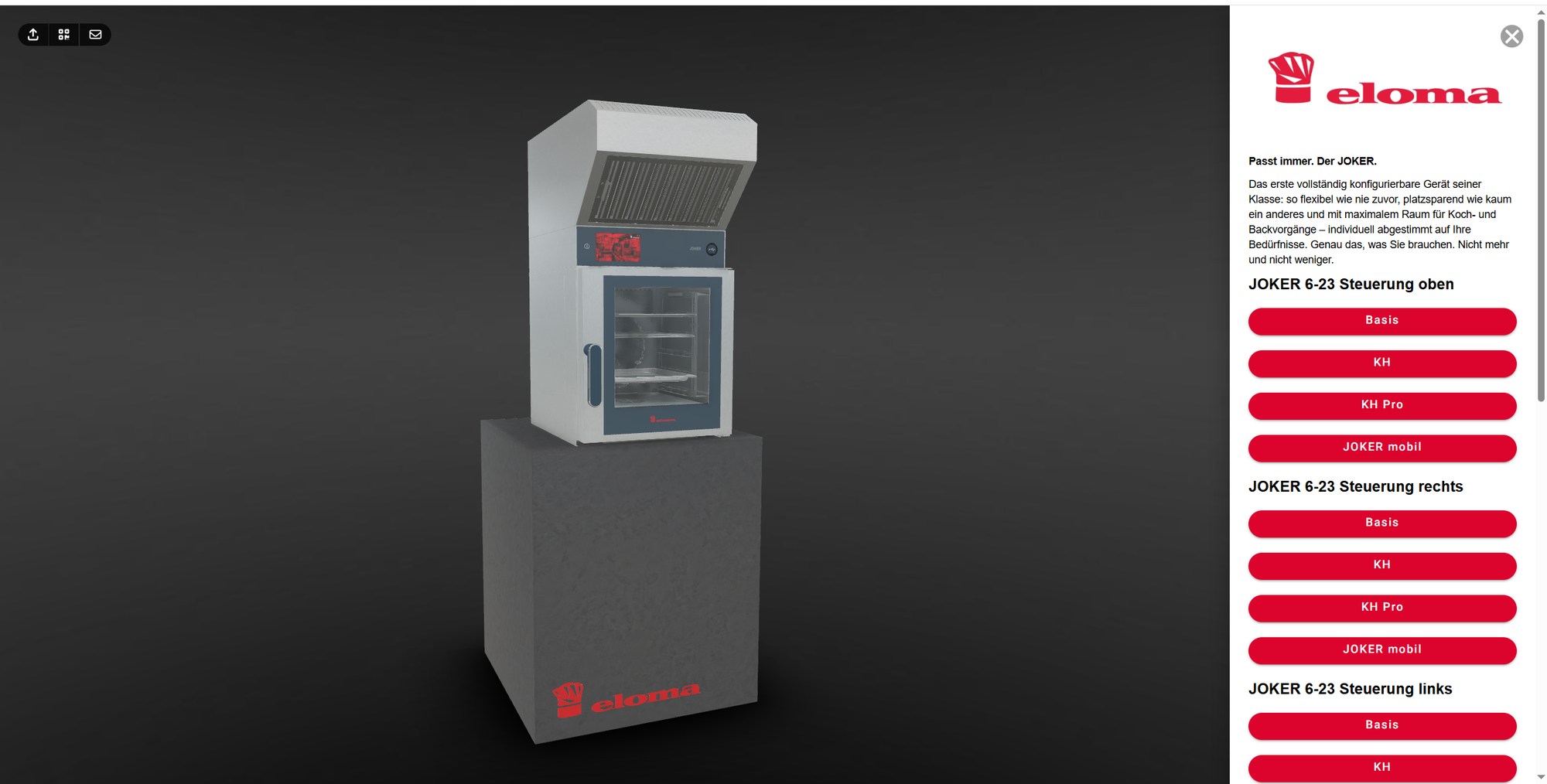

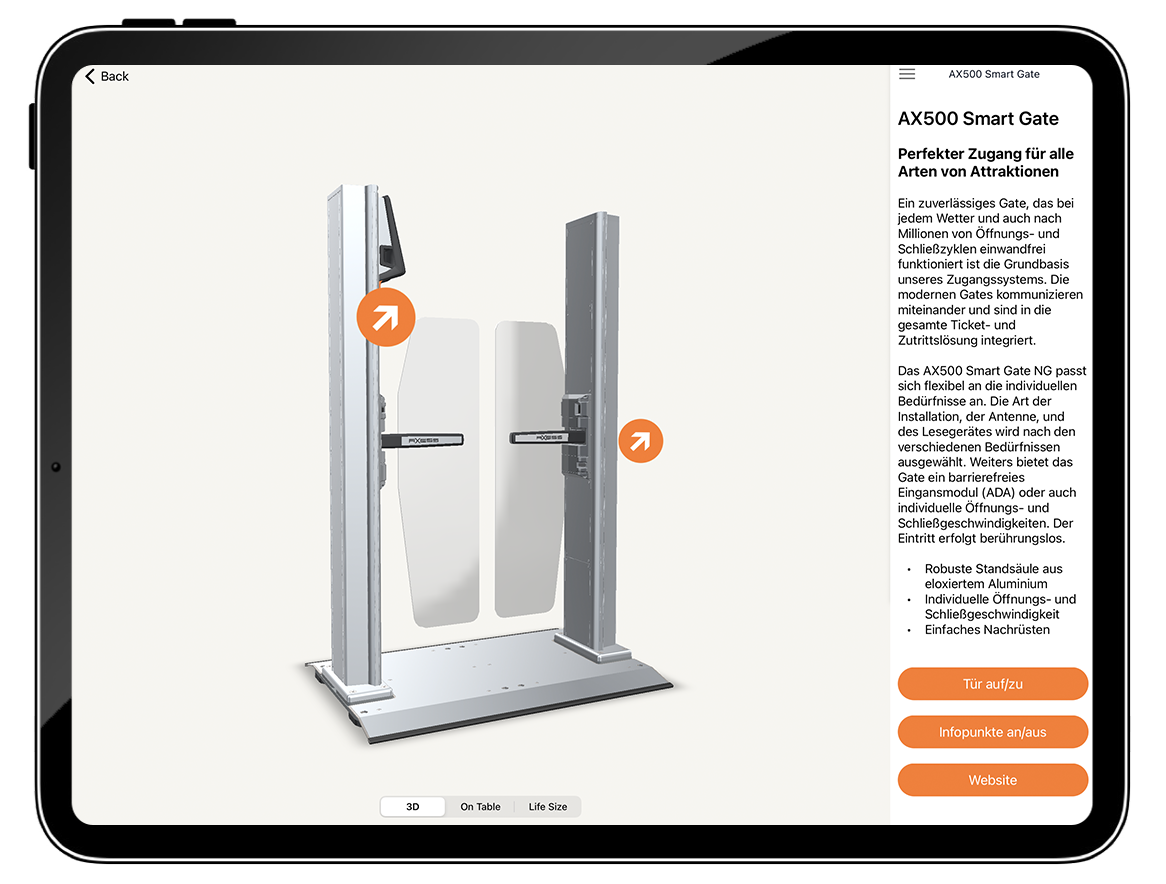

In the pharmaceutical manufacturing industry, understanding complex tablet press machinery has traditionally meant navigating dense technical manuals and 2D engineering drawings. Fette Compacting is changing that paradigm with SmartVu® technology—a breakthrough 3D visualization platform that brings their precision machinery to life through interactive, animated presentations.

SmartVu® transforms how operators, maintenance technicians, and engineers interact with Fette Compacting equipment. Instead of static images, users can now explore fully rendered 3D models of tablet presses, view animated sequences of compression cycles, and observe intricate mechanical movements in real-time. The technology allows for 360-degree rotation, component isolation, and cross-sectional views that reveal internal mechanisms previously hidden from view.

Key Features in Action:

The animated capabilities shine brightest during training and troubleshooting scenarios. Watch as the turret rotates through its compression cycle, with each punch and die station clearly labeled and color-coded. Animated sequences demonstrate proper assembly procedures, maintenance protocols, and operational workflows with unprecedented clarity. Users can pause, rewind, and replay critical processes until full comprehension is achieved.

For Fette Compacting's FE series and Perfecta models, SmartVu® provides transparent overlays showing tablet flow paths, force distribution patterns, and timing sequences that were previously only theoretical. This visual intelligence reduces training time by up to 40% while significantly improving operational understanding and maintenance accuracy.

https://share.vuframe.com/dbd506d1